Uh...Decision Made

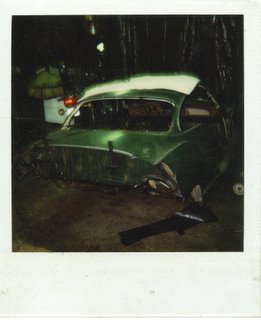

Ahem....OK, the decision had been made, the coupe would be 'vert fodder. Hard to see in the pic, but the chop had begun.

I acquired the coupe in about 1992. By late '92 I'd finished my graduate degree work and was in the process of changing jobs. Ghia work was slow and came in fits and starts. In early '94 I was placed on on-location assignment in Augusta, Georgia. In late '94 after that assignment ended, I was offered an assignment in Manila, Phillipines. No chance to work on the Ghia there, either. I had to make a decision with regard to the cars. I had been shopping around for someone who knew metal work since it was clear I was not going to take on this work myself. Eventually I located Schirmer Welding shop in Norwood, Ohio (a so-called suburb of Cincinnati - which is actually completely surrounded by the city). The Schirmer brothers had lots of experience salvaging rust bucket older generation VW's as well as other hobbyist cars like Mustangs and Corvairs. The Schirmer's are knowledgeable, honest, down to earth, hard working and are just as interested in talking to you about your baby (your kids, too) as they are in doing the work on your car. I also considered, visited and spoke to Mark Schlacter of Metalkraft Coachwerkes, which is just down the street in Cincinnati. Mark seemed more interested in dissuading me from engaging his shop for my needs (by impressing me with all the work/money that was going into the Classic/Vintage VW's, Porsches and Mercedes in his shop) than in discussing my humble Ghia project. I'm sure Mark does A-1 quality work, but I wasn't dissuaded from the amount of work/dollars, just his approach! If you've got a high end German resto and the requisite disposable income, Mark's your man. At that time, I was on the learning curve and wasn't up to being patronized.

Next move: I toted the 'vert's body and the new old pan to the Schirmer's shop, and hauled all of my others parts and the coupe to a storage locker up the road from their shop. This way, they could have access to the coupe and any necessary parts while I was on assignment overseas. I really trusted these guys that much and I can say now, they didn't let me down. I have been under and around every inch of the car recently and all of the work is as good quality as I would expect, solid work with no corners cut.

Next move: I toted the 'vert's body and the new old pan to the Schirmer's shop, and hauled all of my others parts and the coupe to a storage locker up the road from their shop. This way, they could have access to the coupe and any necessary parts while I was on assignment overseas. I really trusted these guys that much and I can say now, they didn't let me down. I have been under and around every inch of the car recently and all of the work is as good quality as I would expect, solid work with no corners cut.You can see here that by this time the rear end of the coupe has been cut away. The Schirmers needed access to all of that coupe metal in order to be able to piece my 'vert's undersides back together. Turns out that they took the vert body, cut it in half along the rocker channels (what was left of them), turned the halves upside down, and proceeded to do all of the under body metal work from below (kind of like having a car rotisserie, if you have seen that approach, but with out the actual device). Then they set the halves back down on the pan and proceeded to piece the rocker channels back together. Incredible!

0 Comments:

Post a Comment

<< Home